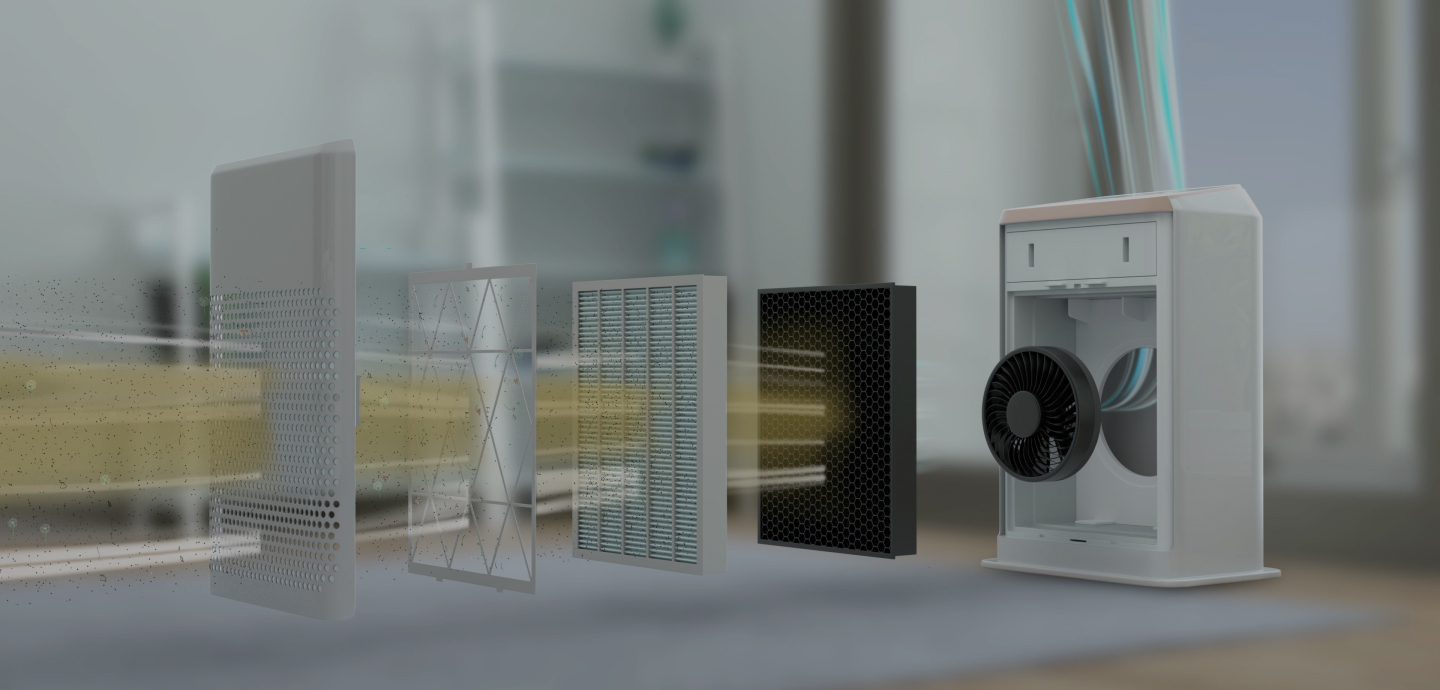

The majority of positive and negative isolators, laminar flow units, non-ducted fan filter units, balance enclosures, Class I biological safety cabinets, and some Class II B2 biological safety cabinets have prefilters. Prefilters are critical to help remove larger dust particles and extend the life of the HEPA filter, the blower motor, and components. If prefilters are not changed out regularly, they can cause imbalanced airflows and pressures in the unit, thus causing the device airflows to fall outside the manufacturer’s acceptable range of protection for the patient, product, personnel or environment.

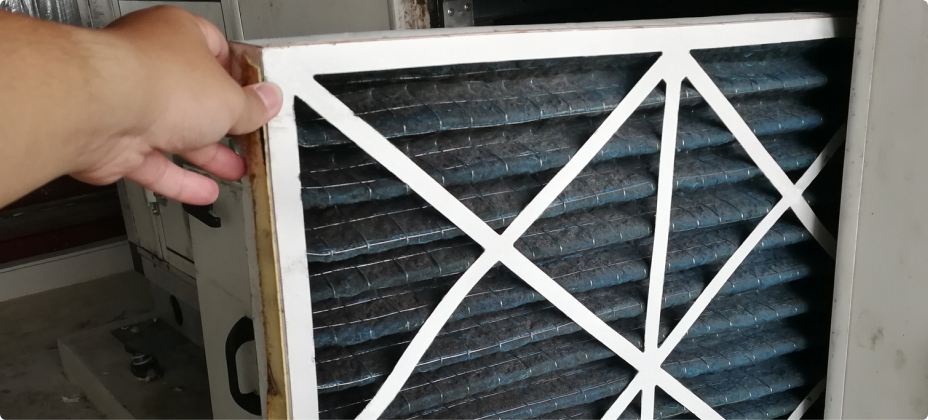

Dirty vs. New Prefilter

Side by side comparison of a dirty and new prefilter

Device and fan filter unit prefilters are typically similar to residential furnace filters; however you should contact Air Safe or your manufacturer to find out which prefilter should be utilized for your equipment and where they are located. The incorrect placement of the prefilter into the prefilter housing is a consistent issue observed in the field, in particular with isolators. Many isolators have a lip around the top opening upon which a prefilter can be set. If that prefilter is pushed down too far, it can cut off the intake blower and cause airflow and pressure spikes or deficiencies.

Prefilters should be replaced, or thoroughly cleaned if they are a washable type. on a routine basis. It’s recommended you check prefilters on a regular basis (possibly weekly but at maximum monthly) to determine how long it takes for your particular prefilter to become loaded, which in most cases is 3-6 months. Once you have established a proper timeline for filter loading, it’s recommended you set up a preventative maintenance schedule for prefilter replacement. In some configurations a prefilter may be monitored with a pressure monitor. In these cases, the readings should be logged on a regular basis and a maximum and minimum pressure tolerance should be established to indicate when replacement or action is necessary.

Don’t forget to double check that your prefilters are seated correctly and are adequately clean for usage on a regular basis. This simple step could go a long way to help save you the cost of replacing the HEPA filters, motors or additional components sooner than later.